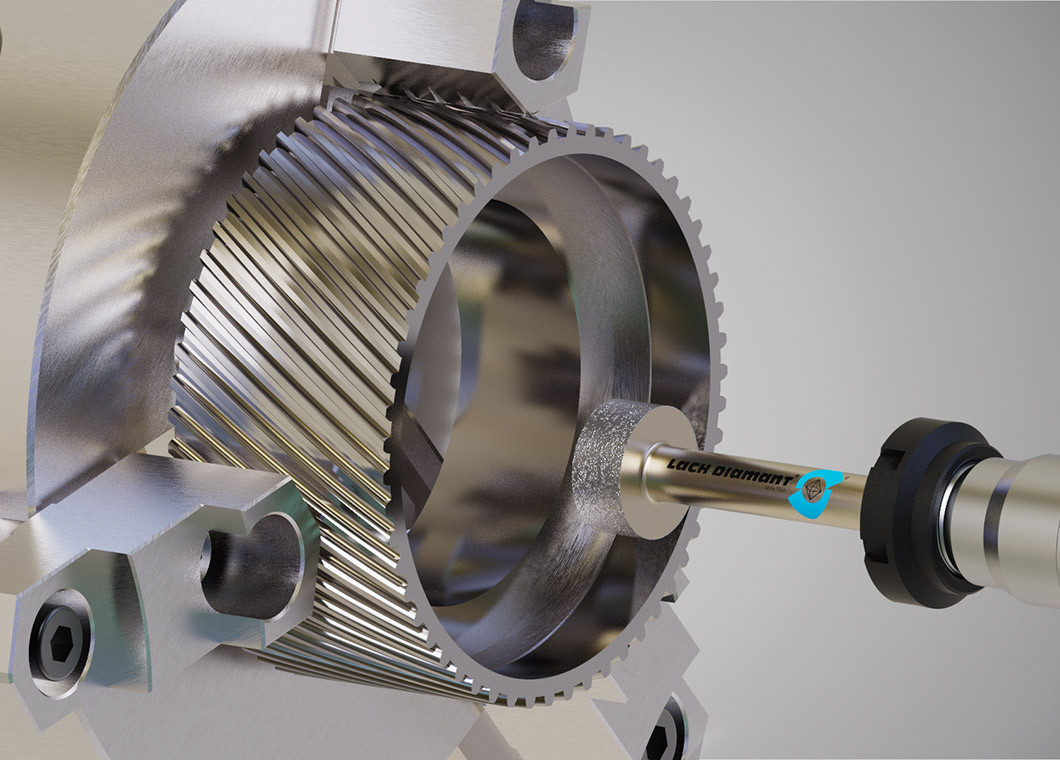

Internal cylindrical grinding

of high-alloy steels and HSS

CBN grinding meets highest demands

The internal cylindrical grinding process is mainly used to make cylindrical or tapered bore holes. It is important to distinguish between plunge grinding and longitudinal grinding. Special challenges are the difficult chip removal, the targeted cooling lubricant supply as well as low removal rates in case of unstable parts. Therefore, particular attention has to be paid to the selection of grinding wheels for this application.

High removal rates

Short grinding times –

long tool lives

Low heat generation

High surface quality

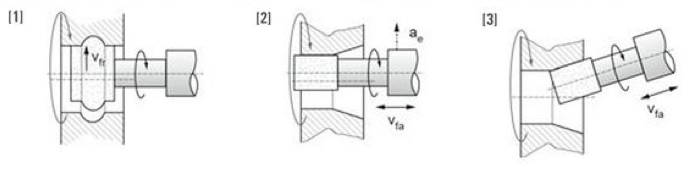

[1] and [2] internal cylindrical – peripheral – cross grinding, [3] internal cylindrical – peripheral – longitudinal grinding

References: Conrad, Klaus-Jörg (Hrsg.): Taschenbuch der Werkzeugmaschinen, 3. Auflage, München: Hanser Verlag, 2015. S. 645-647

The contact lengths – the arcs of contact – are the longest and largest of all grinding processes, plus, the cooling lubricant supply right at the contact surface is difficult so that open-pored systems such as the ceramic bond will achieve the best results in the high-performance sector.

Download

News

100 Years LACH DIAMANT – Part 7

25/10/2023

100 Years LACH DIAMANT – Part 5

04/05/2023

100 Years LACH DIAMANT – Part 4

03/03/2023