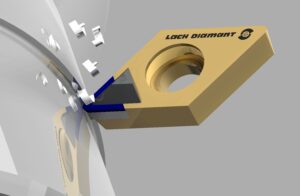

The machining of GRP and CFRP calls for special know-how. Meanwhile, diamond tools – either with diamond or PCD – belong to the standard repertoire for the processing of any type of composite materials.

LACH DIAMANT tools are highly innovative, work with highest precision and increase economic efficiency by a multiple.

Wide variety of uses on all current machines in wind turbine and rotorblade processing: CNC, robotic and manual milling machines.

For more than 20 years the LACH DIAMANT engineers have been working with the challenging material and with their experience and intuition – have supported the wind power industry in becoming „greener“:

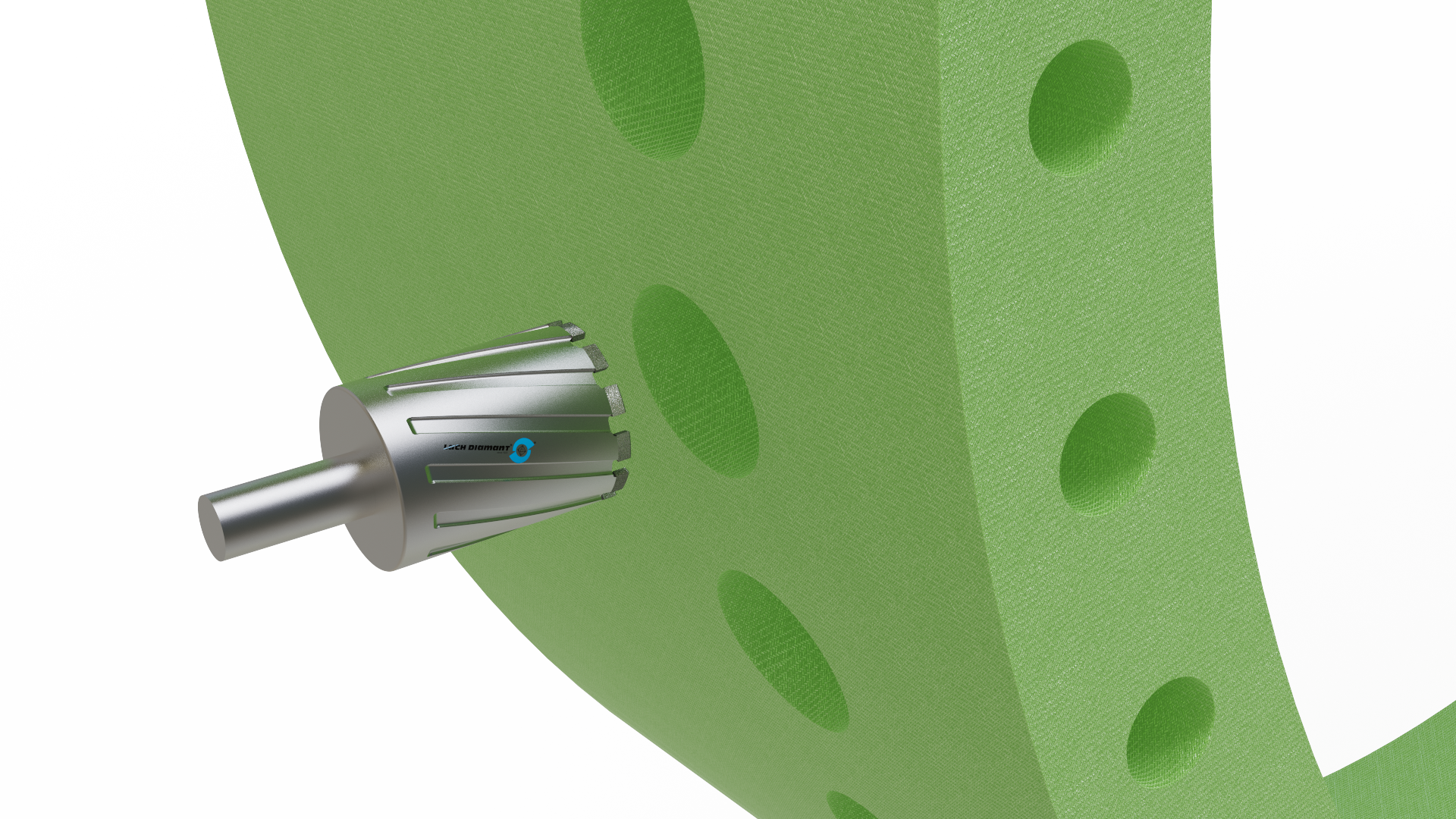

The drill with internal exhaustion for a dustfree and precise drilling operation.

Innovation: PCD drills with internal exhaustion

Tools with diamond or PCD ensure a precise processing of this highly abrasive material and with maximum infeed, tool lives and reduced production cycle times.

The economic efficiency of diamond tools in this processing step is out of reach for carbide tools.

PCD-tipped cutting saws

long tool life

high infeed rates increase the machine utilisation

high efficiency

Tools can be resharpened and re-tipped several times

diameters from Ø300 to 550 mm

Cutting saws with diamond coating

diamond coating by means of electroplating process

cost-effective solution

easy to use

recoatable multiple times

diameters from Ø300 to 550 mm

The LACH DIAMANT high-performance face milling cutters allow maximum face milling accuracy with a low degree of delamination. High feed rates reduce machining times by a multiple. Internal coolant channels for longer tool lives of the high-performance cutting tools. The PCD cutting edges can be re-sharpend and/or re-tipped with PCD several times.

Also LACH DIAMANT solid drills with PCD cutting edges allow delamination-free bore entrances and outlets.

The extra-hard cutting material allows maximum feed rates reducing production times by a multiple. Internal coolant channels for longer tool lives. The PCD cutting edges can be resharpend and/or re-tipped with PCD several times.

also available with integrated internal exhaustion (A LACH DIAMANT innovation – see Highlight)

recommended for CNC machines

diameters from Ø20 to 100 mm

for SK or HSK adapters

low cutting forces

low vibration

reduced chip formation

bore diameter Ø30 – 150 mm

for SK or HSK adapters

recommended for robotic systems

diamond coating by means of electroplating process

cost-efficient alternative

low cutting forces

low vibration

minimal burr formation

bore diameter Ø30 – 150 mm

recommended for robotic systems

Besides the production of the above mentioned tools we develop customised solutions for your specific application. Special dimensions are manufactured according to your requests and requirements.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions