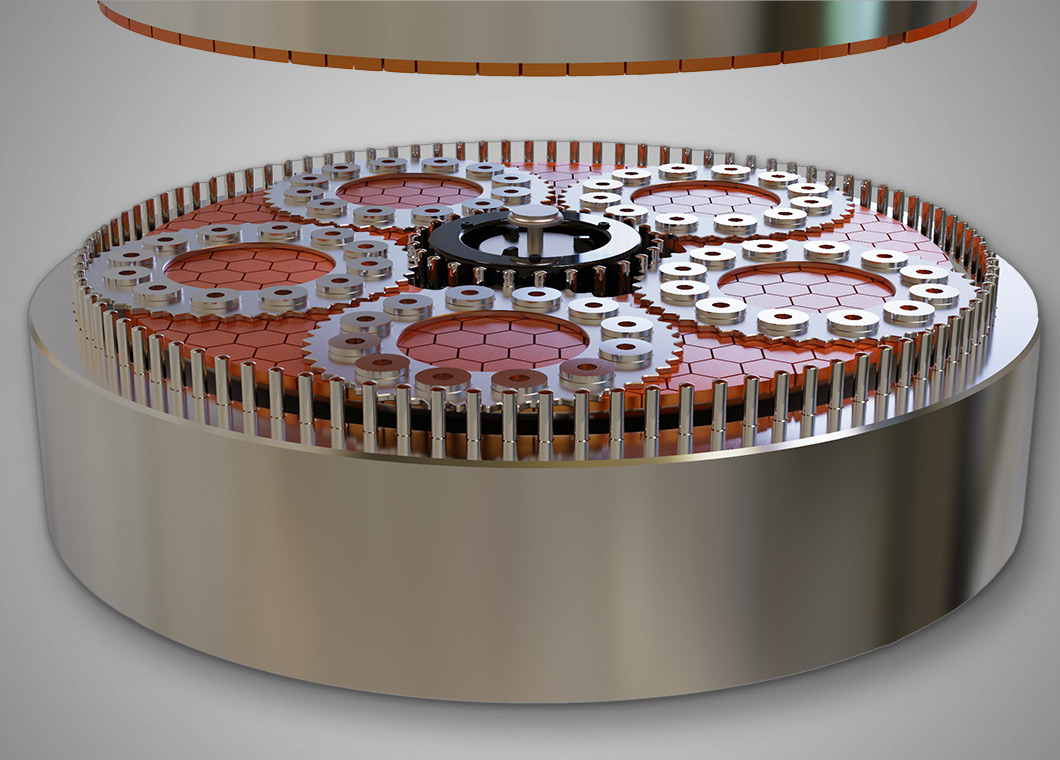

The process for the economical production of parallel workpieces.

High-precision grinding wheels enable high plane parallelisms and flatnesses with exceptional surface qualities. Thus, machining accuracies can be achieved even with large grinding inputs and high machining volumes, which in many cases previously required lapping operations.

Grinding wheels up to a diameter of 1600 mm are specially produced according to the workpiece requirements:

Adapted bindings (plastic, ceramic or metal) with matching diamond or CBN grain qualities increase performance and meet every surface requirement.

Maximum efficiency due to highly developed resin, ceramic or metal bonds

Tolerances smaller than 1µ for flatness and plane-parallelism

Surface roughness up to 0,03µ

Removal rates of up to 800 µ/min

Further information of Double Disc Surface Grinding Wheels, simply click download.

In addition, we offer diamond and CBN grinding wheels for surface grinding applications.

We look forward to finding the customised solution for your application.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions