Startpage > Industries > Circuit Boards > Depanelling

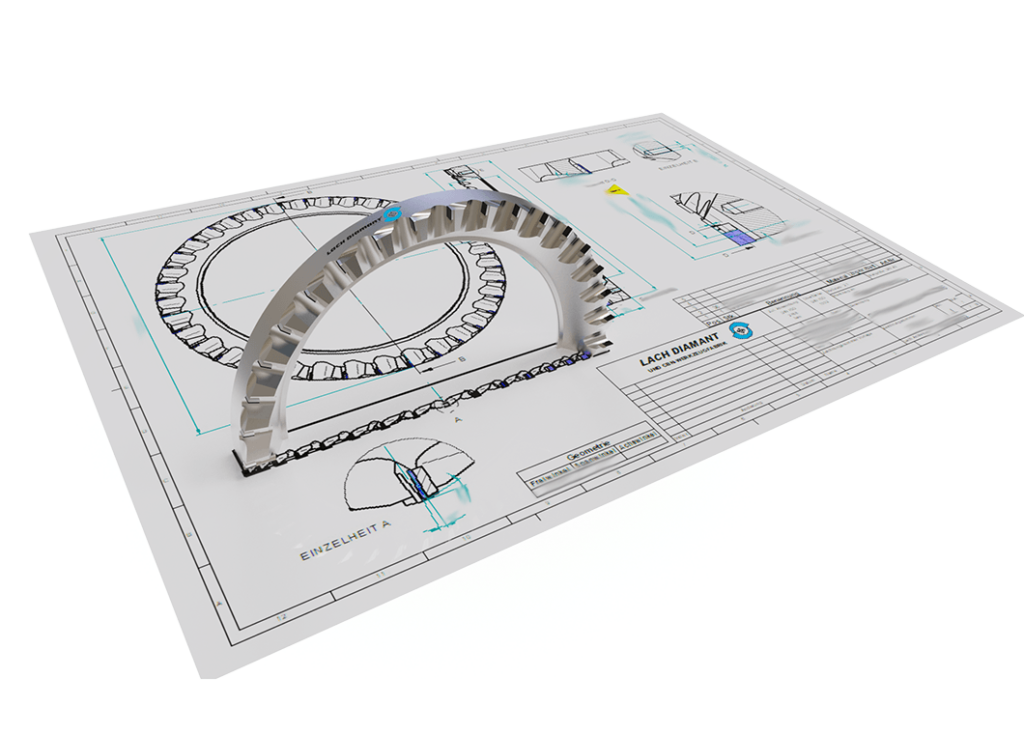

The diamond or solid carbide depanelling saws stand out for their high cutting performance and high quality cutting edges – meeting even extreme edge requirements.

In the depanelling sector LACH DIAMANT offers different types of depanelling saws.

The electroplated version of diamond depanelling saws is recommended for highly abrasive materials.

Now things go round!

LACH DIAMANT rounds off its product range “depanelling” with solid carbide contour routers.

They are available with spiral and diamond toothing. Both versions stand out for their perfect cutting edge geometry for their depanelling task: free-form contours.

These high-precision tools are manufactured in Germany – according to German quality standards.

The toothing of the solid carbide depanelling saws is optimally adjusted to the material to be processed.

The finest toothing version minimises the frequency formation to avoid causing shocks to the components.

A rougher toothing is recommended for the low-stress depanelling of IMS materials.

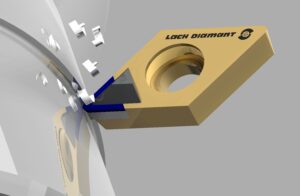

Depanelling of highly abrasive materials like ceramics or PCB with a high glass-fibre content poses a challenge to the tools: short tool lives and tooth breakings are common.

The LACH DIAMANT solution: Electroplated diamond cutting discs

The diamond grit size which is suitable for the specific application is applied to the basic body by means of electroplating. Cutting widths up to a minimum of 0,4mm are possible.

Along with the manufacturing of our standard products we develop tailor-made solutions for your specific application. Special dimensions are manufactured according to your request and demand.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions