Startpage > Industries > Electric motor manufacturing

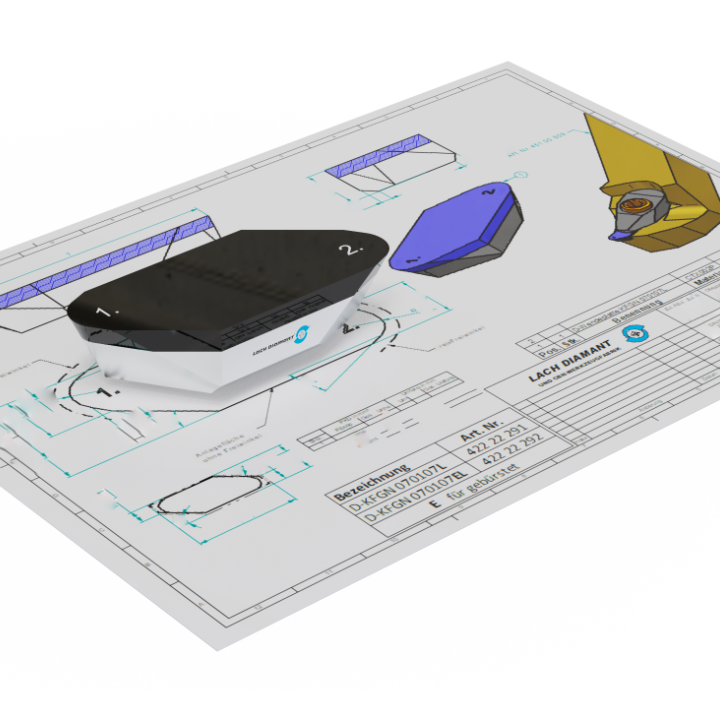

Copper commutators in electric motors require a high-precision surface quality which is achieved by using polycrystalline diamond (PCD). K-inserts for corner radius turning, round inserts with 12-segments (for multiple use) for peel turning or T-inserts for both turning operations: PCD provides precise surfaces and achieves maximum tool lives.

PCD-tipped wear parts stand out due to minimal friction and low wear in comparison with carbide, cermet or ceramic wear parts.

PCD-tipped wear parts will be manufactured according to your application. We will lift your operation onto the next level to higher efficiency.

The PCD-tipped stripping knives cut the insulating layer of the copper wire with maximum repeat accuracy and low wear:

Turning tools with polycrystalline diamond (PCD) cutting edges are successfully used for processing aluminium and all non-ferrous metals. CBN, the second hardest cutting material, is considered to be a guarantee for success for turning hardened steels.

Curious about our turning programme? Get more information here.

Along with the manufacturing of our standard products we develop tailor-made solutions for your specific application. Special dimensions are manufactured according to your request and demand.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions