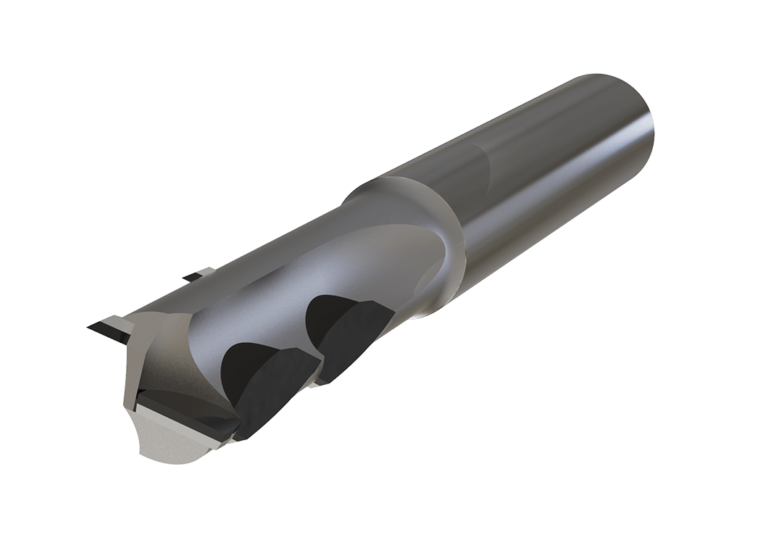

End mills with PCD cutting edges are indispensable for the processing of highly abrasive materials like GRP, CFRP, green ceramics, graphite and non-ferrous metals. The ultra-hard cutting edges allow delamination-free cuts with the desired level of quality.

Different versions with adapted number of teeth, cutting and axial angle and cutting edge configuration allow roughing and finishing operation. The LACH DIAMANT engineers develop PCD end mills for your specific application.

The high-quality PCD cutting edges can be reground and/or replaced in our Inhouse-service.

Type SMS / SMS ECO

The end mill type SMS with two PCD cutting edges is used for the high-end processing of all non-ferrous metals, GRP and CFRP.

Also available in the economical ECO version for the precise processing of green compacts, graphite, GRP and CFRP.

Type SMP

The positive cutting angle of the PCD end mill type SMP is suitable for the processing of sensitive and thin-walled components made of non-ferrous metals and plastics (GRP, CFRP).

Type SMM

3 to 5 PCD cutting edges allow the roughing of components made of non-ferrous metals and plastics (GRP, CFRP, graphite, green ceramics).

Type SMV

PCD cutting edges for roughing thin-walled components made of non-ferrous metals and plastics (GRP, CFRP).

Type SMSWA

The PCD end mill with shear cut application allows the high-precision edge processing of green ceramics, graphite, GRP and CFRP.

Application: roughing and finishing

Type SMSXX

The use of PCD cutting edges with extreme shear cut is recommended for for finishing sensitive composite materials like GRP, CFRP, aluminium. The ultra-hard cutting edges allow for precise edge processing and a delamination-free cut.

Our catalogue about the LACH DIAMANT milling tool range will provide a detailed overview of the LACH DIAMANT PCD end mills.

Together with you the LACH DIAMANT engineers will find the suitable PCD end mill for your application. We look forward to hearing from you.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions