For the optimum machining of GRP, CFRP and non-ferrous metals

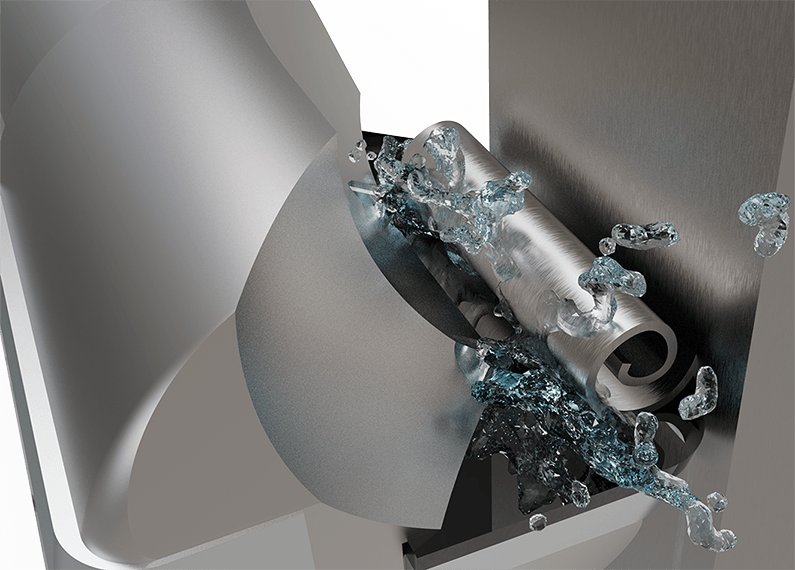

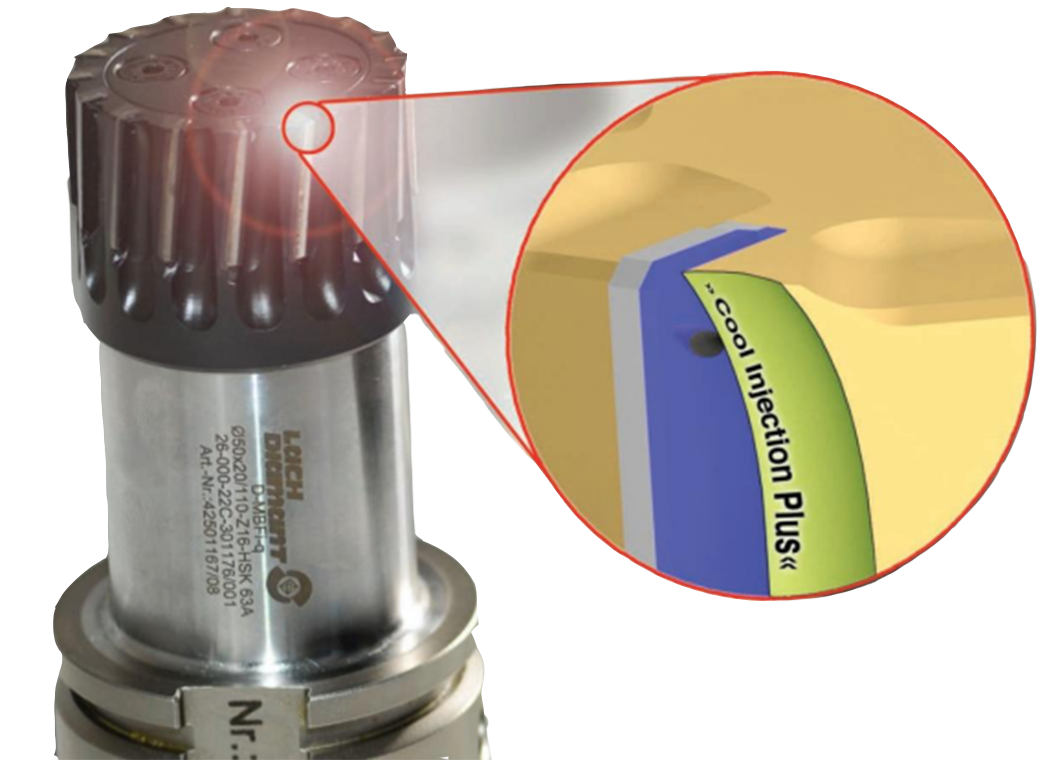

With this LACH DIAMANT innovation the coolant – emulsion, oil, MMS or for cryogenic cooling – is directed through the open cutting face of the PCD edge: directly under the chip being generated.

The system »Cool Injection-Plus« guarantees process-reliable, controlled and efficient machining.

»Cool Injection-Plus« for an even more process-reliable machining with the »dia-compact«-monoblock diamond milling cutter.

»dia-compact«-screw-in monoblock diamond milling cutter with »Cool Injection-Plus« ensures an optimal chip removal.

An extended overview of the LACH DIAMANT diamond milling cutter programme with the »Cool Injection-Plus« system, please refer to our flyer and catalogue on LACH DIAMANT’s milling range.

Our LACH DIAMANT engineers will work with you to find the diamond milling cutter with the »Cool Injection-Plus« system for your machining needs. We look forward to hearing from you.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions