Milling with PCD and CBN is LACH DIAMANT’s supreme discipline. Our experts develop PCD tools exclusively with PCD tipping. We are proud of our numerous innovations which have made possible today’s milling processing in the first place.

The use of polycrystalline and monocrystalline diamond promises highest efficiency – combined with the know-how of the LACH DIAMANT engineers you will receive milling cutters for an ideal optimisation of your application.

The monoblock diamond milling cutter is a LACH DIAMANT innovation.

Used for the face and square shoulder milling of GRP, CFRP and of all aluminium alloys, it proves maximum efficiency and high productivity.

The novelty: the innovative compact design allows a higher number of teeth and thus extremely high cutting speeds (HSC) and feed rates from 0.05 to 0.20 per tooth.

For roughing, finishing and fine-finishing of GRP, CFRP and non-ferrous metals.

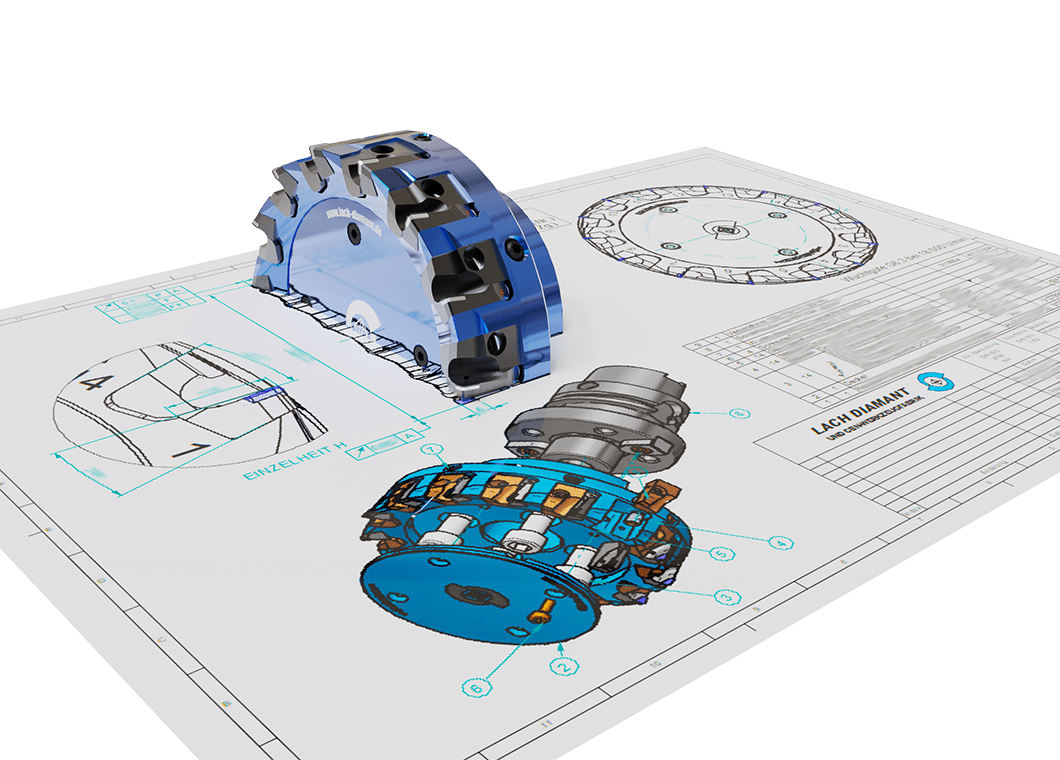

The PCD cartridge milling cutter »dia-blue-power« combines the advantages of Monoblock tools and conventional insert milling cutters offering easy handling.

Due to its innovative component quality, positive cutting angles and shear cut, the LACH DIAMANT PCD cartridge milling cutter stands out through high efficiency and guarantees both stability and flexibility.

For the optimal machining of GRP, CFRP and non-ferrous metals.

With this LACH DIAMANT innovation the coolant – emulsion, oil, MMS or for cryogenic cooling – is directed through the open cutting face of the PCD edge: directly under the chip being generated.

The »Cool Injection-Plus« system guarantees process-reliable, controlled, efficient machining.

LACH DIAMANT milling cutters are as varied as their applications: In close cooperation with our customers we develop customised high-performance tools for their specific applications.

We should be glad to develop the appropriate diamond tool for you – together with you.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions