We have developed a metal bond with new composition. The revolutionary features? The exisiting deficiency of metal bonds – a low removal rate – is eliminated by this innovation.

This opens up new – and hitherto unimaginable – optimisation possibilities for the series production of all types of profiles in carbide, hardened steels and ceramics.

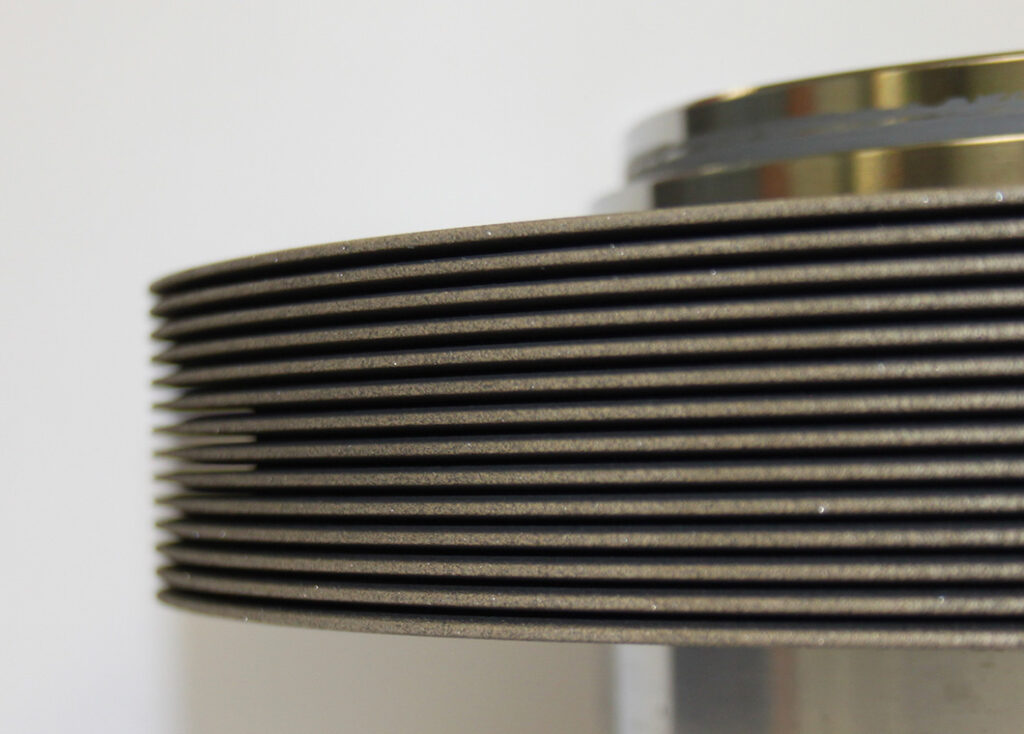

Thus, the previously necessary multipass grinding of the profile with several grinding wheels is now replaced by only one “contour profiled” wheel – even in case of complex profiles. It plunges into the solid with infeeds of 15 mm in one step.

High precision

Tolerances up to 0,005 mm – for external and internal radius.

High time savings

35% to 60% higher feed rates per workpiece are possible.

of the diamond or CBN layer

25 times longer profile stability*

one single profiled grinding wheel replaces the previously necessary set of wheels*

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions