Here, we answer your basic questions about cutting materials, their benefits, differences, and applications. If you have any further question, feel free to contact us.

PCD stands for polycrystalline diamond. It is a synthetic diamond produced by compressing diamond powder under high pressure and temperature. PCD is characterized by its exceptional hardness, wear resistance, and thermal conductivity. These properties make PCD an ideal material for manufacturing high-precision cutting tools and abrasives for industrial processing of various materials.

What are the advantages of using PCD tools? PCD tools offer a range of advantages, making them a preferred choice in various industrial applications:

High hardness and wear resistance: PCD is one of the hardest materials used in the industry. This exceptional hardness makes PCD tools extremely resistant to wear, resulting in longer tool life.

High thermal conductivity: PCD possesses excellent thermal conductivity, efficiently dissipating heat generated during the cutting process.

High surface quality and low burr formation: This results in extended tool life, less rework, less scrap, and consequently lower labor costs per component.

Universal applicability: PCD tools are suitable for processing a wide range of materials, including non-ferrous metals, plastics, composite materials, ceramics. This versatility makes PCD an ideal solution for various machining applications.

Environmentally friendly: Since PCD tools last longer and require less frequent replacement, they generate less waste and lower resource consumption, making them an environmentally friendly choice.

High cutting performance and precision: Thanks to their hardness and wear resistance, PCD tools offer high cutting performance and enable precise machining with high surface finish and dimensional accuracy.

Reduced machining costs: Due to their longer tool life and higher cutting performance, PCD tools can reduce the overall operating costs of machining. Fewer tool changes and less wear mean less downtime and higher productivity.

Overall, PCD tools offer a combination of hardness, wear resistance, thermal conductivity, versatility, and precision, making them an excellent choice for demanding machining applications in various industries.

CBN stands for cubic boron nitride. It is a synthetic crystalline substance consisting of boron and nitrogen and structurally similar to diamond. CBN is characterized by its exceptional hardness, wear resistance, and thermal conductivity, making it ideal for machining hard materials such as hardened steel, cast iron, cemented carbide, and other difficult-to-machine materials.

CBN is used in a variety of applications, especially where diamond is not suitable due to chemical reactions or other limitations. It is commonly used in the manufacture of cutting tools such as grinding wheels, inserts, drills, and milling cutters. CBN tools enable precise and efficient machining processes with high surface finish and minimal tool wear.

PCD (polycrystalline diamond) and CBN (cubic boron nitride) can be used in machining various materials due to their exceptional properties, including:

Non-ferrous metals (e.g., aluminum): PCD tools are excellent for machining metals due to their exceptional hardness and wear resistance. They enable precise and efficient machining processes with high surface finish and minimal tool wear.

Composite materials (such as fiber-reinforced composites and composite materials): PCD tools are successfully used for machining carbon/glas fibre reinforced plastic (CFRP/GRP), offering high tool life and low delamination effects.

Ceramic: PCD is also suitable for machining ceramic materials due to its hardness and wear resistance, allowing precise cuts and surface finishing with high quality.

Cemented carbides: CBN tools are particularly suitable for machining cemented carbides due to their exceptional hardness and wear resistance, allowing precise cutting and high surface finish.

Hardened steel: CBN tools are ideal for machining hardened steel, providing high cutting speeds and tool life, reducing machining times, and increasing productivity.

Cast iron: Cast iron can also be efficiently machined with CBN tools, as they exhibit high temperature resistance and wear resistance

PCD (polycrystalline diamond) is not suitable for the following applications:

Machining of ferrous materials: Due to the high affinity of carbon to the element iron, PCD tools may prematurely wear or damage when machining ferrous materials such as steel and cast iron.

Very high temperatures: PCD has a limited operating temperature of about 700 degrees Celsius. At temperatures above this value, chemical reactions may occur, destabilizing the diamond structure and leading to premature tool failure.

Applications with strong impact loads or vibrations: PCD may be susceptible to damage from sudden impact loads or vibrations, especially when used in insufficiently stable or vibration-damping machining environments.

Applications requiring special coatings: In some specialized applications requiring a specific coating to reduce friction or improve heat dissipation, PCD may not be the optimal choice.

It is important to carefully consider the specific requirements of the machining application and select the appropriate cutting tool accordingly. In some cases, alternative cutting materials such as CBN (cubic boron nitride) may be the better option to achieve the desired machining results. Therefore, LACH DIAMANT has both options in their tool programme.

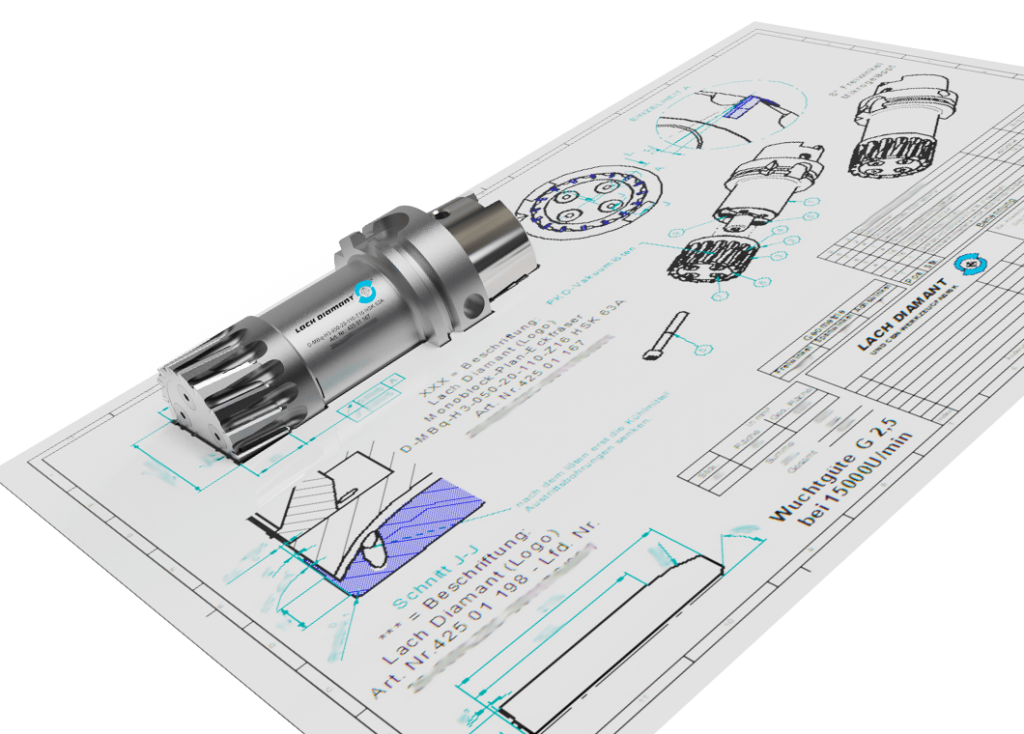

LACH DIAMANT tools offer numerous advantages compared to conventional tools. These include significantly longer tool life, higher cutting speeds, more precise machining results, and less rework. Additionally, they enable improved surface finish and dimensional accuracy of workpieces, as well as a reduction in scrap and downtime.

Yes, LACH DIAMANT products comply with international quality standards, ISO 9001 and ISO 14001, and are manufactured using state-of-the-art production technologies. The company places great emphasis on quality and precision in all its products and processes.

Yes, LACH DIAMANT tools also offer environmentally friendly benefits. As they have a longer lifespan and require less frequent replacement than conventional tools, they reduce waste and resource consumption. Moreover, their high efficiency and precision optimize machining processes, leading to less energy and material waste.

Yes, LACH DIAMANT offers tailored training, technical support, and consulting services for the application of its tools. The company has an experienced team of engineers and professionals who assist customers in selecting, applying, and optimizing their tools and processes. Additionally, LACH DIAMANT offers customized in-house training and materials to ensure users can fully utilize the potential of their tools.

If your question is not listed here, please feel free to ask us directly. We look forward to hearing from you.

We look forward to receiving your inquiry in order to develop efficient solutions for your application.

For the optimisation of your production processes we will be glad to provide both support and advice.

Stay up to date with our latest innovations, products, services and upcoming trade fairs. Simply sign up for our newsletter.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions