Foundation of Jakob Lach GmbH & Co. KG: cutting workshop for jewellery diamonds with 600 employees in own facilities

Relocation from Langendiebach to Steinheimerstrasse in Hanau

2nd World War - cessation of activities

Change in business purpose: trade in industrial diamonds for use in dressing tools for the grinding wheel industry

Due to the economic growth the diamond cutting craft came to a standstill and shifted to Israel, India, Russia

Jakob Lach starts trading with industrial diamonds for the dressing of ceramic-bonded grinding wheels in ball bearing and automotive industries.

Horst Lach joins his father's company.

Re-employment of diamond cutters for cutting industrial diamonds.

Start of the manufacturing of natural diamond grinding wheels with metal and resin bonds.

LACH DIAMANT was the first manufacturer worldwide to present CBN-Borazon grinding wheels for HSS tools.

At the Hanover Spring Trade Fair Horst Lach demonstrates for the first time the superior turning of aluminium and copper (commutators) with polycrystalline diamonds (PCD).

Hanover Trade Fair: Presentation of the first PCD diamond milling tools for the cutting of aluminium, wood and plastic materials.

Hanover Trade Fair: First presentation of polycrystalline boron nitride (PCBn) tools for the turning of high-alloy hardened steels.

Horst Lach discovers spark erosion as a tool for the processing and shaping of polycrystalline diamonds (PCD) allowing the cost effective production of PCD tools – milling cutters, saw blades, drills. This groundbreaking invention became Horst Lach's first patent.

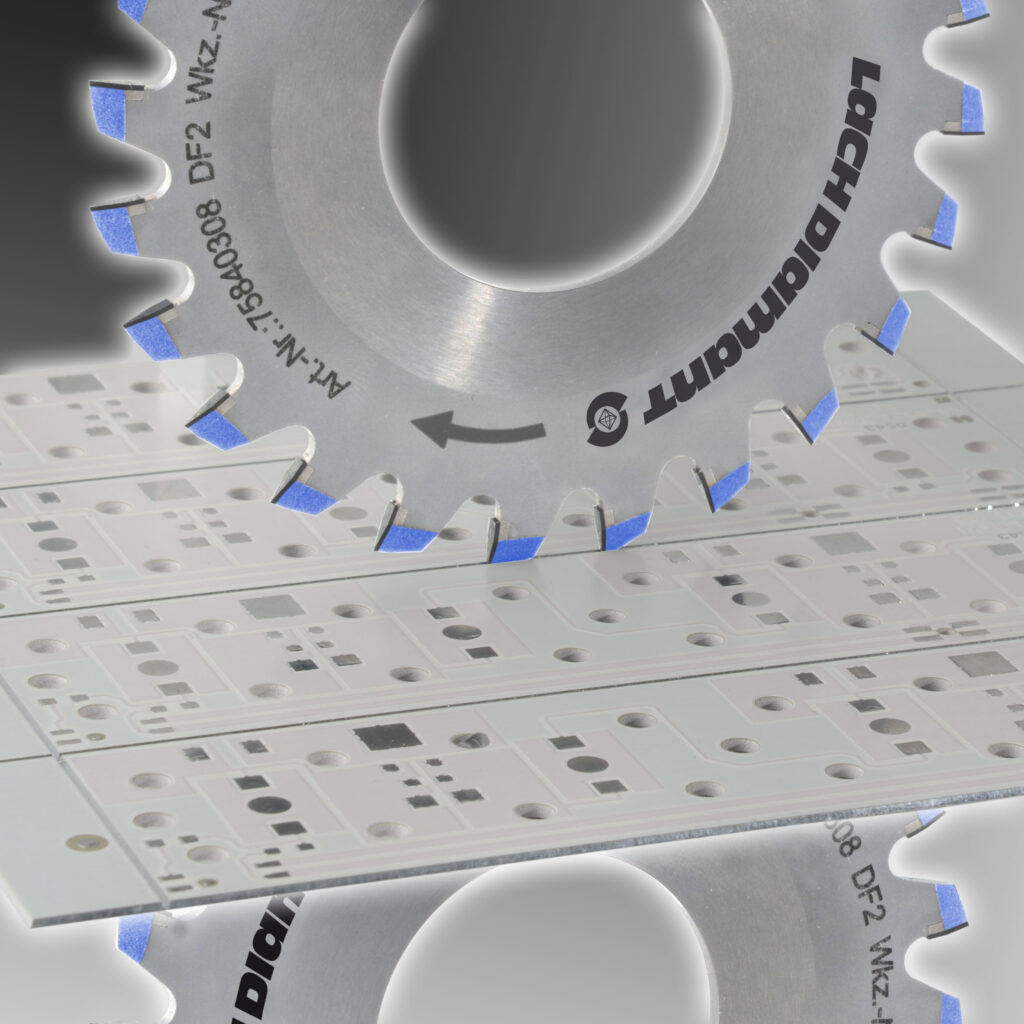

Productronica, Munich: First presentation of diamond tools for the cutting, scoring, sawing and edge processing of printed circuit board materials (PCB).

LIGNA, Hanover: The first presentation world wide of diamond tools (PCD) for the processing of wood, all wood materials and plastics. Only the introduction of PCD tools in the woodworking industry allowed the cost-effective series production of wooden furniture.

FAMETA, Essen: Presentation of the world's first PCD Monoblock milling cutter for aluminium machining.

EMO, Hanover: First presentation of the patented "drebojet" dressing roll with polycrystalline diamond for profiling conventional ceramic-bonded grinding wheels. Thus, the term mill-dressing came into being.

Foundation of LACH DIAMOND INC, Grand Rapids, Michigan, USA

Relocation to the newly built headquarter in Donaustrasse, Hanau

LIGNA, Hanover: Presentation of the new universal sharpening machine "EDG" for the spark erosion processing of PCD – which has initially been developed for inhouse use since 1978.

Robert Lach, engineer, joins the company.

LACH DIAMANT celebrates its 75th anniversary. The newly built plant in Lichtenau near Chemnitz is inaugurated.

LACH DIAMANT received the Diamond Award from DeBeers for 25 years of pioneering work in manufacturing and market development in the polycrystalline diamond tool sector.

Innovation: PCD cutting insert "IC-plus" with chipbreaker for turning aluminium. The patent for short chips revolutionises the world of metal cutting.

The monoblock diamond milling cutter receives the Hessian Innovation Award.

Together with his father Horst Lach, CEO Robert Lach manages the family enterprise LACH DIAMANT.

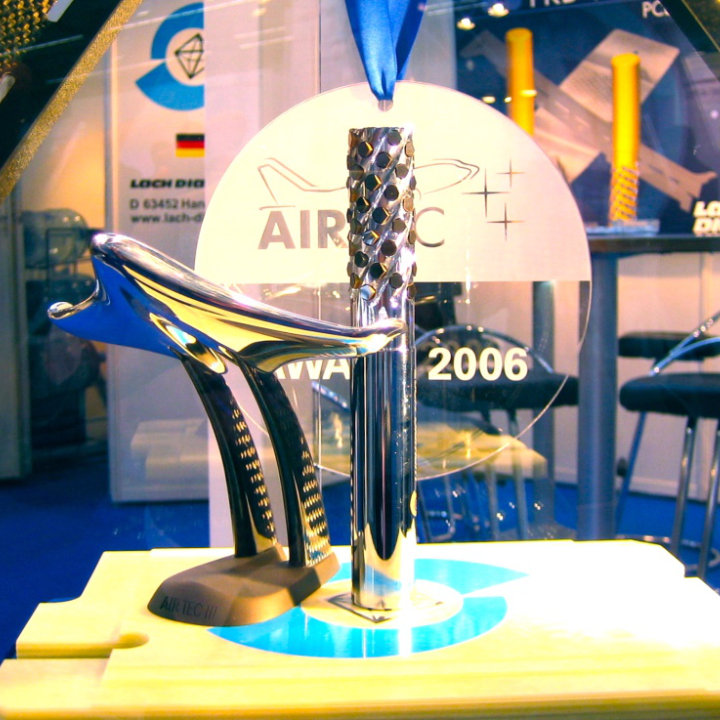

LACH DIAMANT receives the Airtec Award for special developments for the processing of fibre composite materials.

The extension building of the plant in Lichtenau near Chemnitz doubles the production capacity for PCD cutting tools.

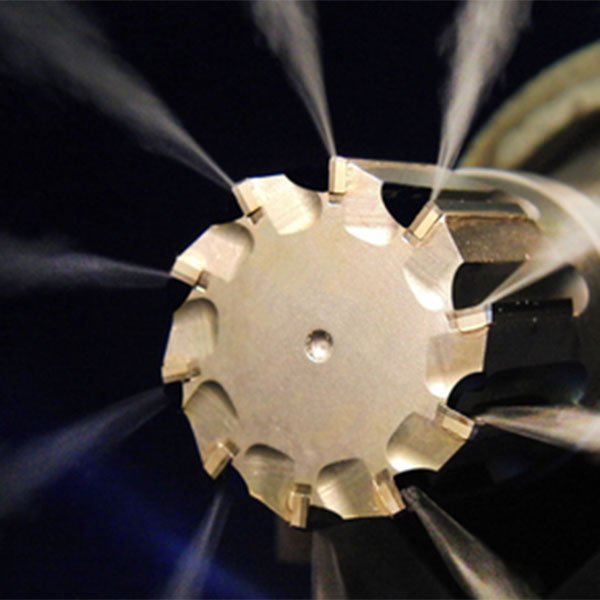

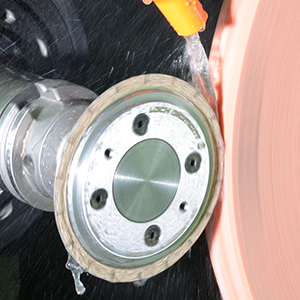

The patent for the "Cool Injection - direct cooling system" is granted.

"Cool Injection" can make diamonds even harder – another innovation.

The LACH DIAMANT plant in Saxony, Germany celebrates its 20th anniversary.

Inauguration of the 3rd construction phase of the Lichtenau plant – production capacity has doubled once again.

13th September: 118th birthday of the company founder Jakob Lach – academic celebration in the German House of Goldsmiths in Hanau – 90th anniversary of LACH DIAMANT

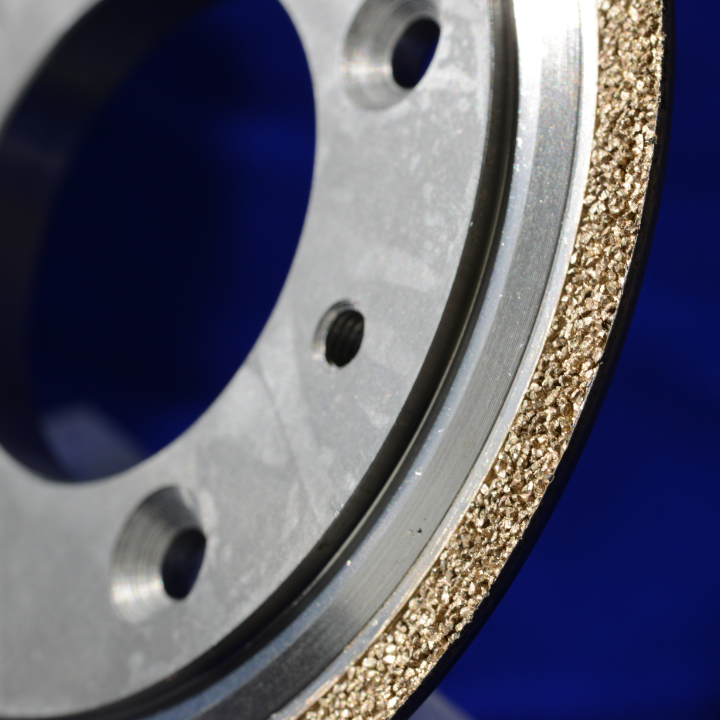

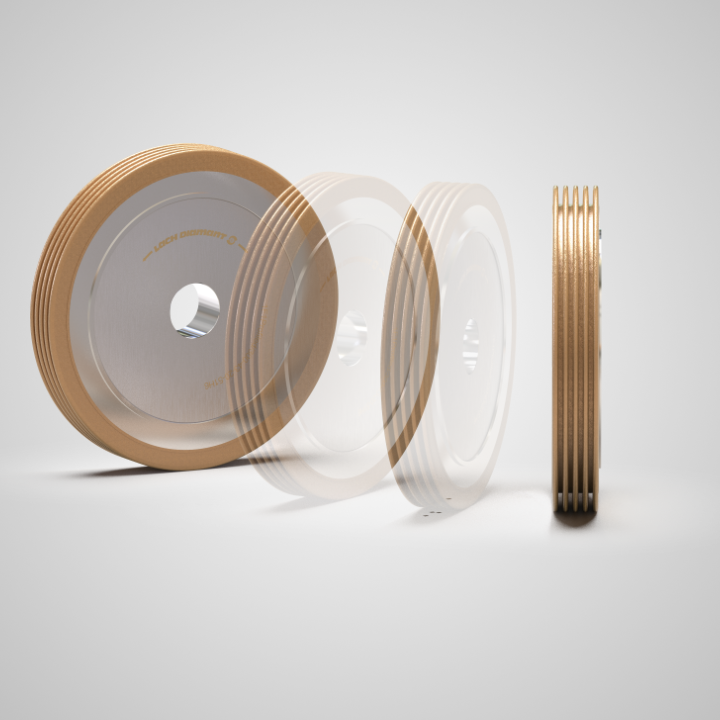

At Grindtec exhibition in Augsburg LACH DIAMANT presents "drebojet-plus" (pat.) precision dressing rolls with innovative formula for the CNC dressing of conventional grinding wheels.

EMO, Hanover: Presentation of the cartridge milling cutter, the complete programme "IC-plus" and of profiled grinding wheels with metal bond.

The new dimension in creep-feed grinding: one for all – contour-profiled grinding wheels for drastical reduction of production costs.

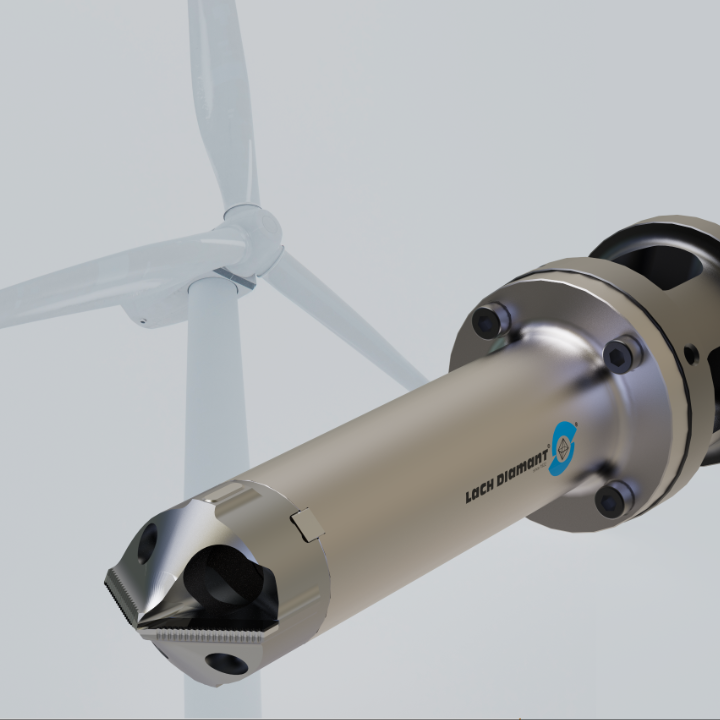

The LACH DIAMANT PCD solid drill sets a new record in the production of wind turbine blades: one drill Ø64 – 400 blades – 80 drilling operations each – drilling depth 130 mm

Thus, with only one drill a wind farm with 133 wind turbines has been manufactured.

100 years of Lach Diamant: The company proudly looks back on 100 years of corporate and industrial history. Numerous products are already waiting in the pipeline, which will continue to inspire the market in the future.

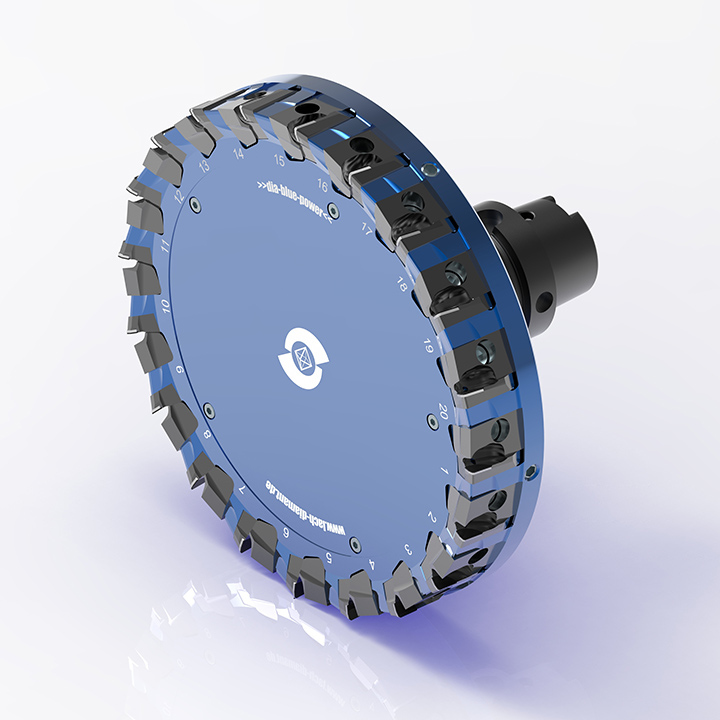

DreboBlueCut hits the milestone of 100.000

The LACH PCD scoring saw reaches new dimensions in terms of tool life: with a number of teeth of only 24 (Z = 24) it cuts – according to highly satisfied customers – more than 100 kilometers of extremely abrasive PCB – this corresponds to the distance between Hamburg and Bremen.

Horst Lach, CEO, reports on the development of diamond and CBN tools in the industry in an ongoing series named “Poly – poly – or what?”

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions