Startpage > Products > Grinding and sharpening machines for PCD processing > »Dia-2200-mini« – Universal sharpening machine

The versatility of the spark erosion machine »Dia-2200-mini« for production and service of diamond tools for the wood and composite industries is now legendary.

The sharpening programmes for the service and also for new production of diamond tools are integrated in the machine without any extra charges and do not need to be installed or programmed.

The programme offers another key advantage: multiple production that will allow automatic resharpening of several diamond tools in only one clamping setup.

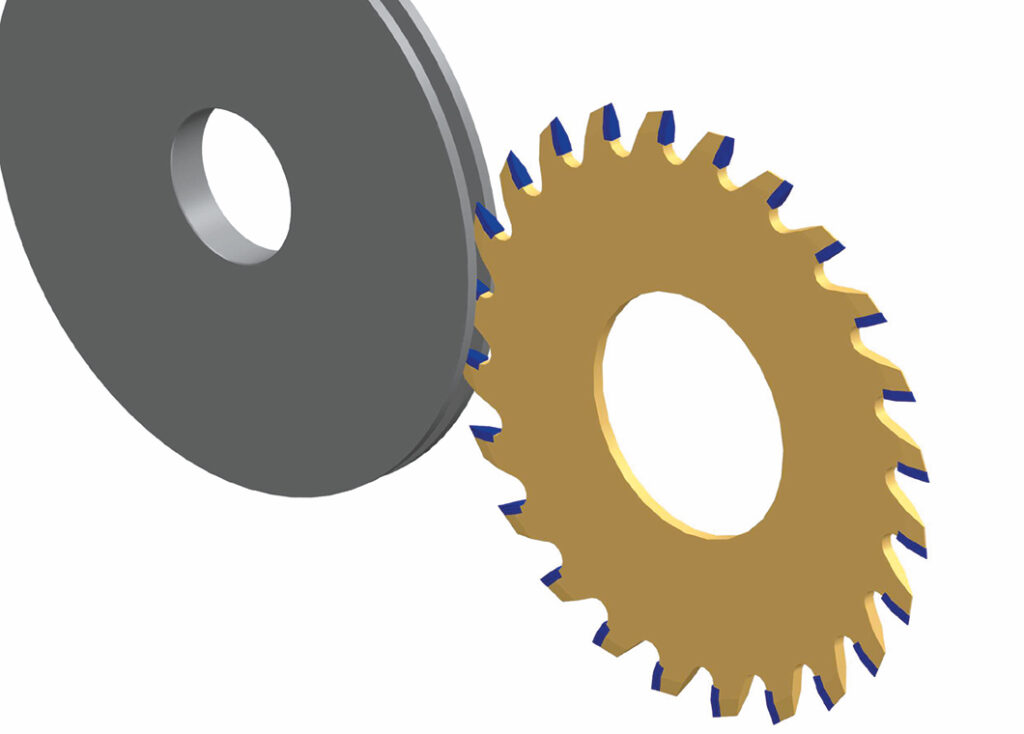

Routerbits, jointing cutters, profile tools or saw blades up to Ø530 mm. Every tool that is received in the everyday service life can easily be resharpened on the »Dia-2200-mini«

After only a few hours of instruction you will be able to resharpen diamond tools with the highest precision. The universal and easy-to-learn concept of the „mini“ sets standards in machine operation

Due to the ergonomic and compact machine design the tools are within easy reach and the machine finds its place even in the smallest hall

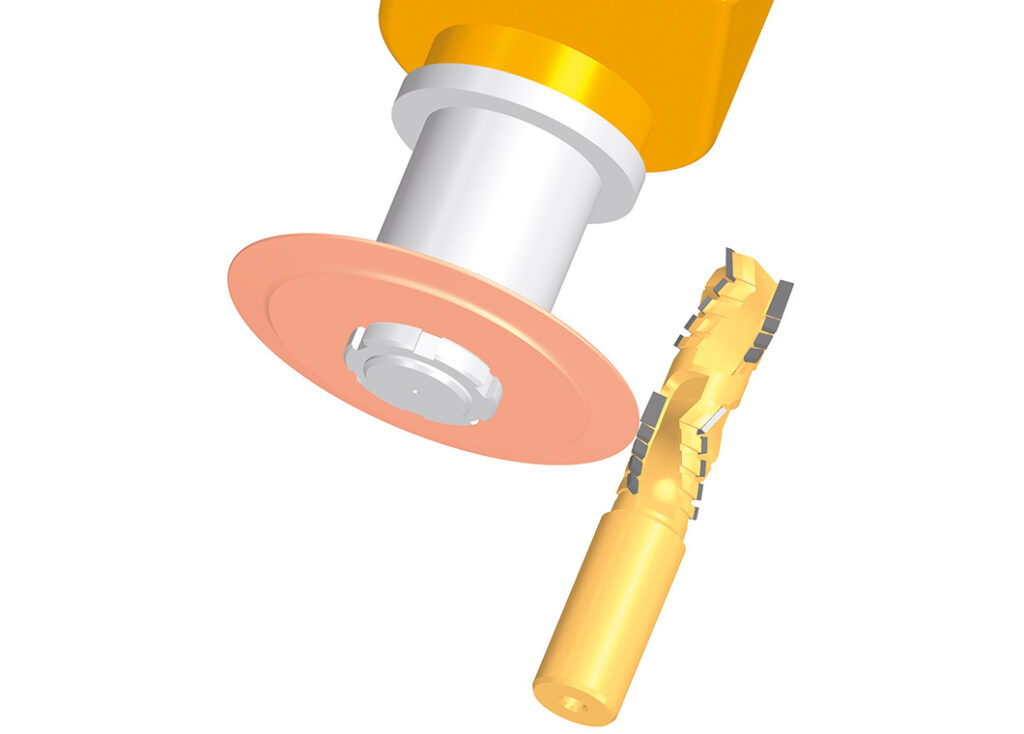

Diamond router bits – shear cut

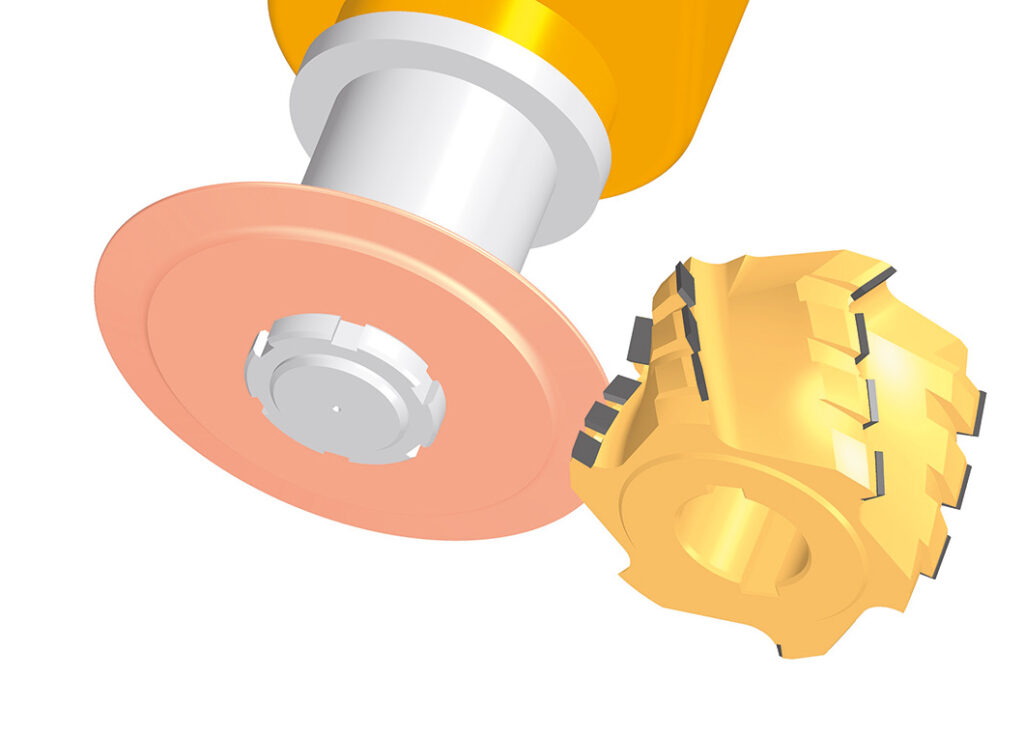

Diamond jointing cutter – shear cut

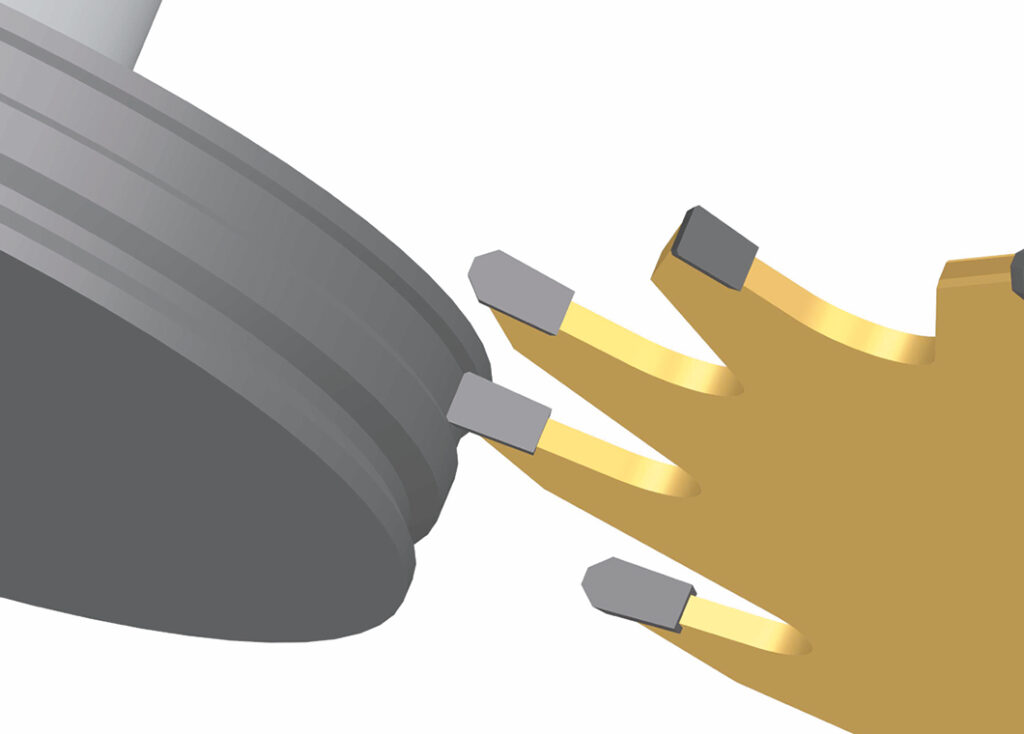

Diamond scoring tools – pointed tooth

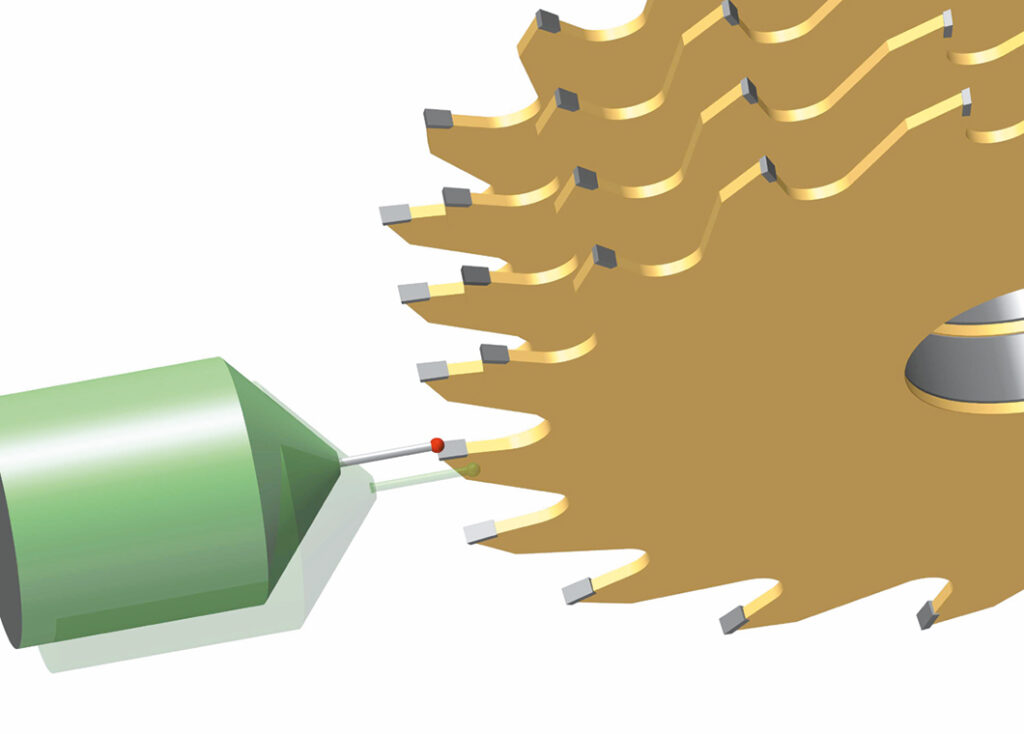

Diamond saws – different tooth shapes

Diamond profile tools

Diamond saws – multiple manufacturing

Not only machine tools are constantly evolving but also the tool division. The modular process control concept of the »Dia-2200-mini« allows the combination of any programme with one another so as to resharpen tools which no one has even thought of yet.

Newcomers in the Dia service business are supported by a clearly laid-out menu guidance on the screen.

Due to the semi-automated set-up function and the video support machine set-up has never been so easy.

Whether tool editor or machine data dialogue, the graphical support explaining every operating window is always present.

The control system, based on Microsoft Windows, allows to reduce complex operations to a few clicks.

Database-supported tool editor:

Store your data locally or on the server. Look for the tool type, tool number or any other data.

Save time and avoid input errors by using the workflow of the »dia-ToolNet« system. Use the »dia-ToolNet« station for central preparation and measuring of all tools. Share your tool data with other machines of the LACH DIAMANT family.

The modular design of the control system allows easy maintenance and repair and provides maximum reliability over the entire lifetime of your »Dia-2200-mini«.

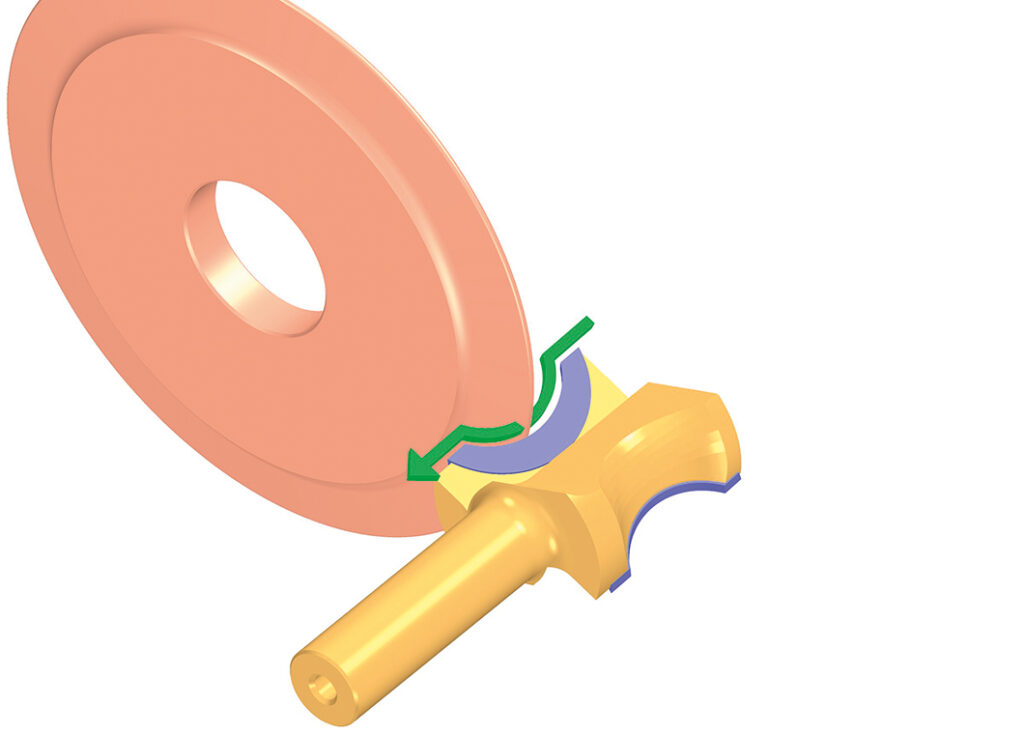

Roughing, finishing and fine finishing have served their time. The digital generator of the »Dia-2200-mini« allows unlimited generator stages. Use the optimal electrode material for your tool and save processing time and costs! Due to the HSK50 spindle mount electrode change is a matter of seconds.

Advantage of the graphite electrode:

Advantage of copper electrode:

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions