Electroplated diamond and CBN bonds allow excellent sharpness of the abrasive layers and very high grinding performances. This benefits single-layered grinding wheels, pins and files.

For electroplated bonds the diamond or CBN grit is embedded in a nickel bond. Grits jut out of the bond by approximately 30-50%, the depth of rim is 1,5 times the amount of the grit size. This enables a resilient bond with high removal rates.

Recommended use: GRP, CFRP, processing of carbide and ceramic green bodies

Special customer-specific versions are possible.

CBN precision grinding pins G-MX 500

Diamond precision grinding pins G-SY

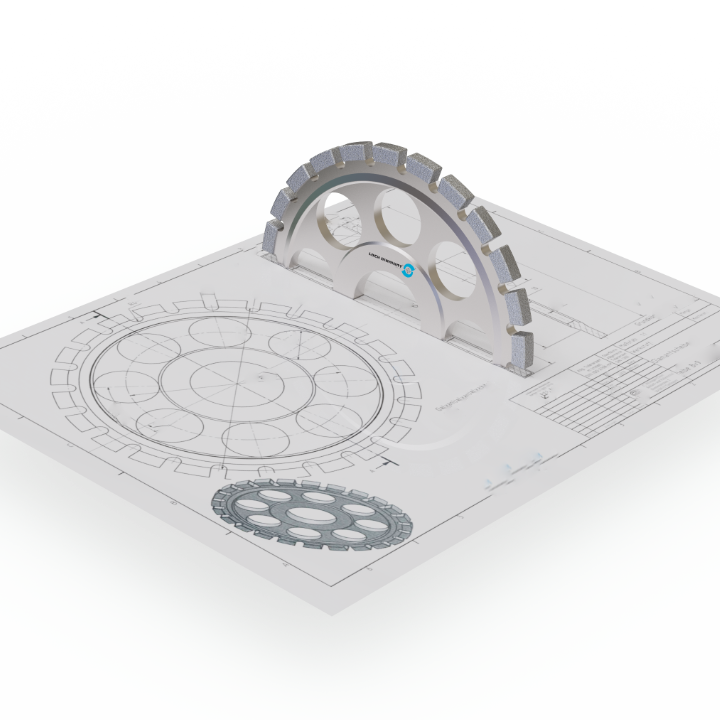

Diamond precision grinding wheels

G-SY

for internal grinding of HSS and hardened steels starting at HRc 55

CBN precision grinding wheels G-MX 500

for internal grinding of HSS and hardened steels starting at HRc 55

Diamond cutting discs G-SY

different types:

Diamond machinist’s files G-SY

Profiles: flat, round, square, triangular, semicircular, flat pointed profile, barette

Lengths from 80–160mm or on request

Diamond grit sizes from fine to extra rough, according to the application

Diamond needle files G-SY

Along with the manufacturing of our standard products we develop tailor-made solutions for your specific application. Special dimensions are manufactured according to your request and demand.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions