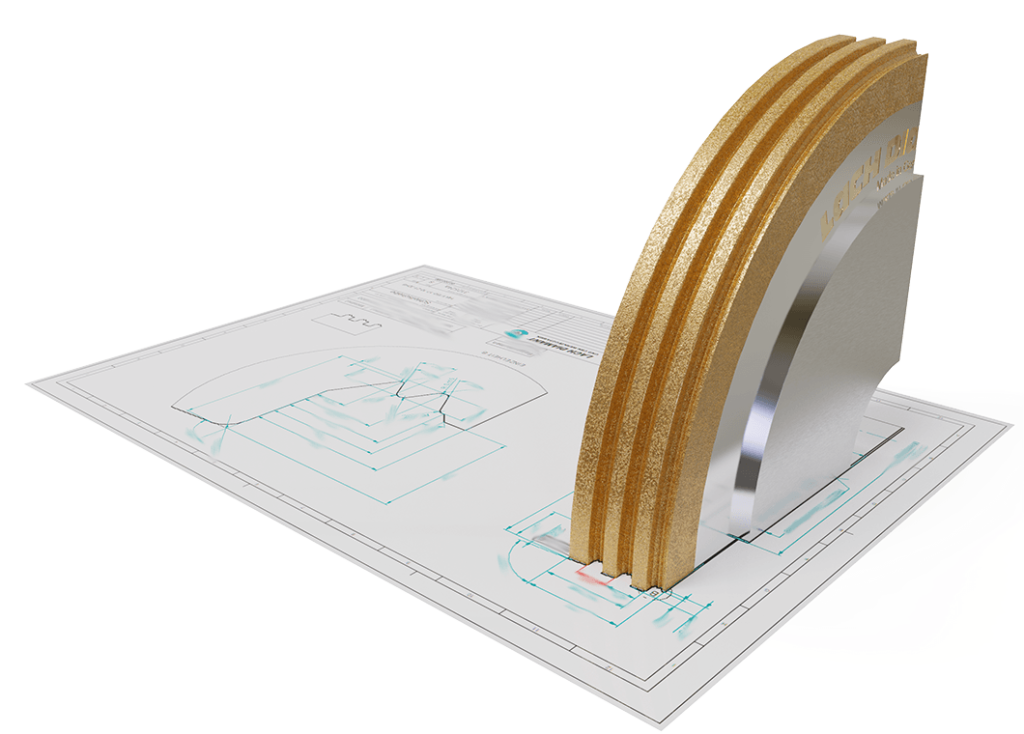

Long tool life, combined with very high removal rates and edge stability

Highest efficiency due to safe, highly precise and long-lasting grinding wheels

The appropriate tool for every grinding process – diamond and CBN grinding wheels – and in addition the complete range of diamond and CBN cutting tools

We have developed a metal bond with new composition. The revolutionary features? The exisiting deficiency of metal bonds – a low removal rate – is eliminated by this innovation. This opens up new – and hitherto unimaginable – optimisation possibilities for the series production of all types of profiles in carbide, hardened steels and ceramics.

Double-disc surface grinding with planetary kinematics

The process for the economical production of plane-parallel workpieces.

High-precision grinding wheels allow maximum plane-parallelism, flatness and exceptional surface quality. For example it is possible to achieve machining accuracies even in case of high grinding allowances and removel rates which hitherto has often required lapping operations.

Grinding wheels with diameters up to 1600 mm are manufactured especially for the workpiece requirements.

Highly sensitive and effective grinding wheel for saw blades

Due to the highly sensitive support system and newly developed bond the grinding of solid carbide saw blades becomes faster, more precise and more efficient.

In addition the results obtained show that the DragonFly grinding wheel works faster and more accurately than conventional wheels at the same tool cost.

DragonFly allows even the grinding of smallest tooth pitches.

The grinding wheels manufactured by LACH DIAMANT in its headquarters in Hanau are as varied and versatile as their fields of use and they are adapted to the respective application.

Along with the manufacturing of our standard products we develop tailor-made solutions for your specific application. Special dimensions are produced according to your requirements.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions