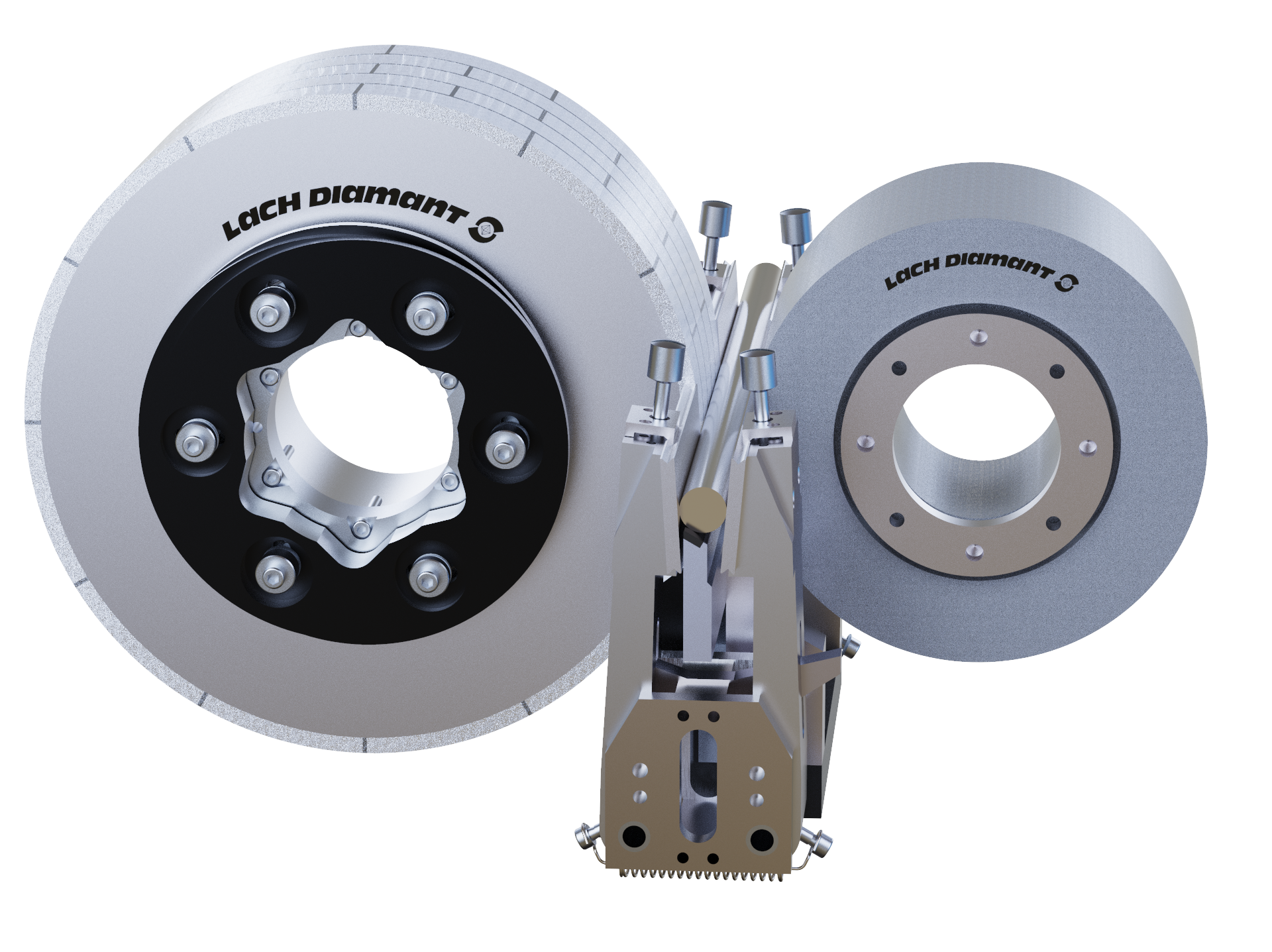

LACH DIAMANT is systems supplier for the centerless grinding process and thus offers technical high-end solutions from one source – and perfectly matched to one another:

The design of the grinding wheel as well as of the control wheel and the dressing tool are directly related to the grinding result. Depending on the machine and application the parameters are coordinated to one another by our application engineers. It is important to pay attention to the workrest blades: special wear protection versions with PCD guarantee constant grinding results.

In the centerless grinding process the workpiece is not located between two centers – hence, the term centerless grinding. Instead, the workpiece lies on a work rest blade between the wheel and a control wheel. The rotation of grinding and control wheel cause the workpiece to rotate and this results in material removal. A distinction is made between plunge and through-feed grinding.

We will be glad to find the customised solution for your application – or simply place your request or order right here.

LACH DIAMANT

Donaustraße 17

D-63452 Hanau

Industries

Custom Solutions